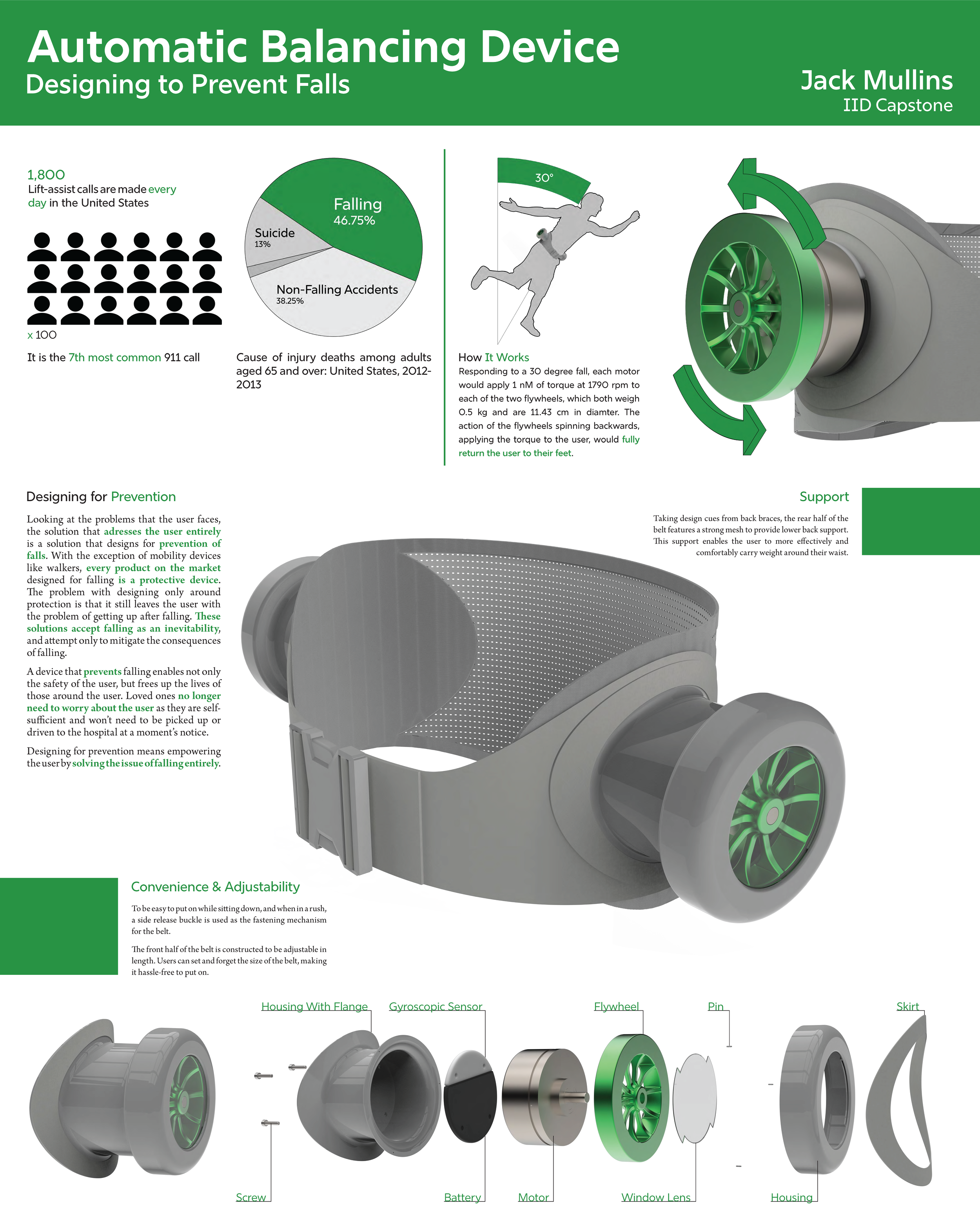

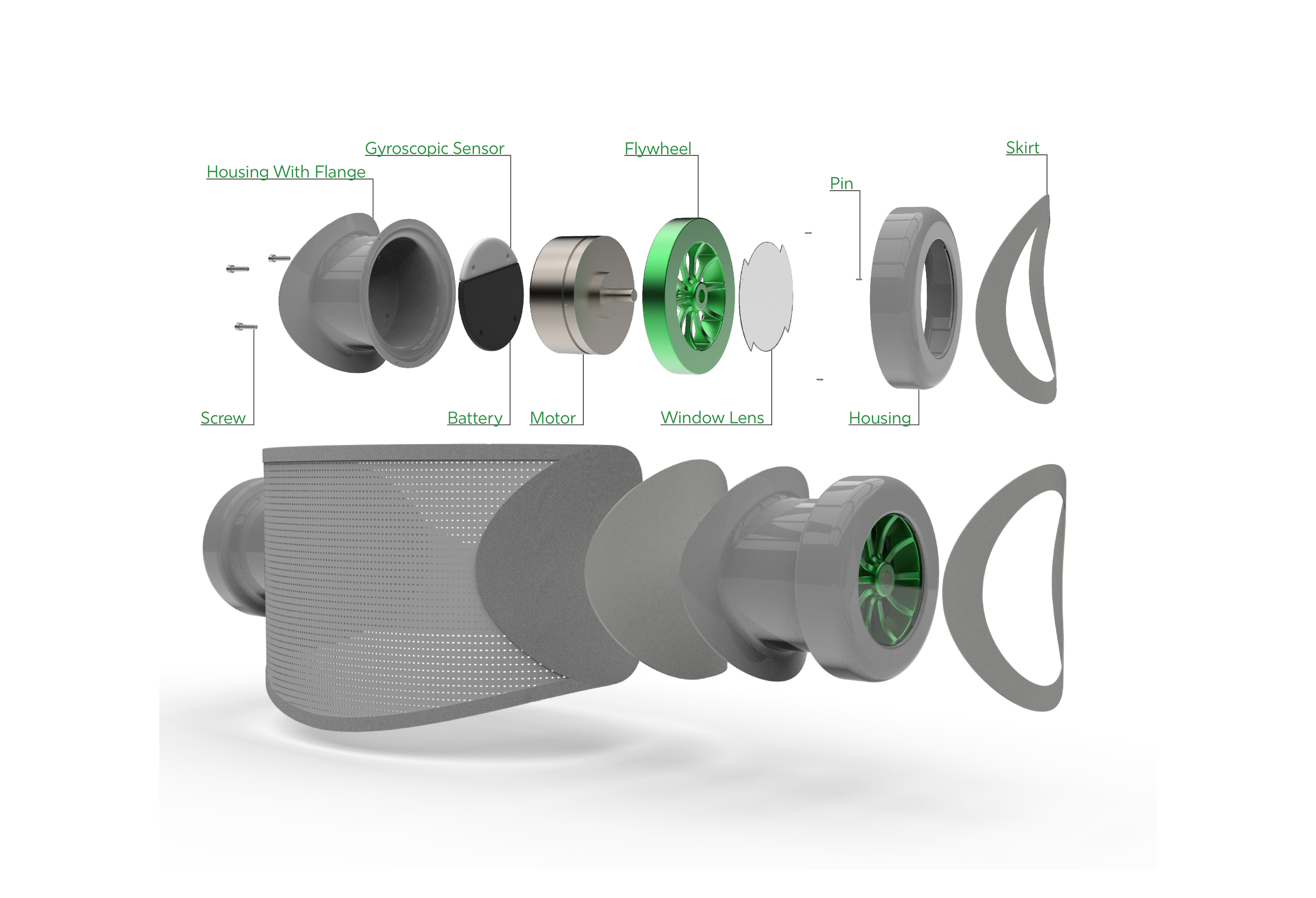

Automatic Balancing Device

Falling is a major issue, and every product currently on the market, with the exception of mobility devices like walkers, serve only to mitigate the consequences of falling. These products treat falling as an inevitability, which allows their users end up on the ground, where they cannot easily get up.

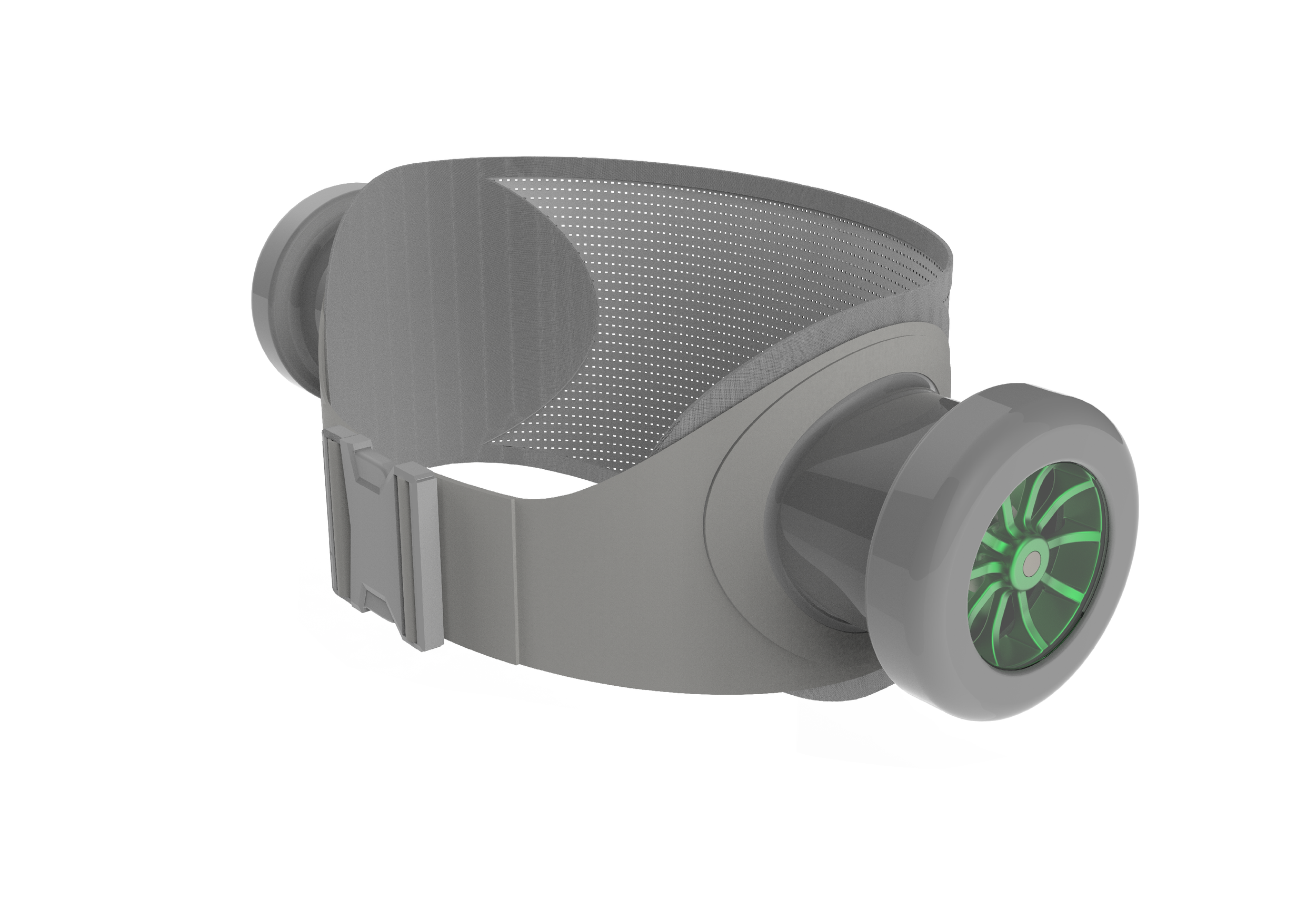

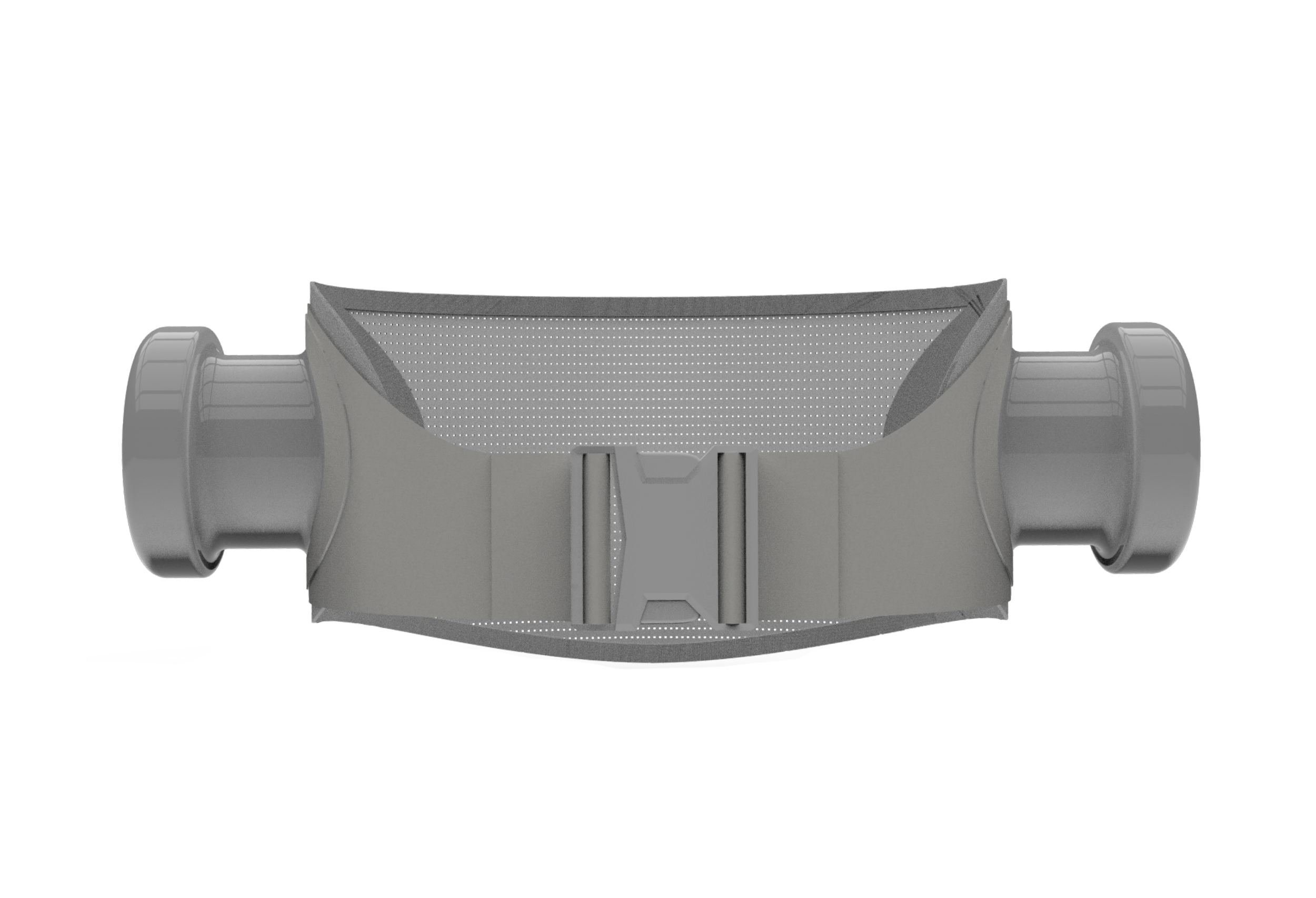

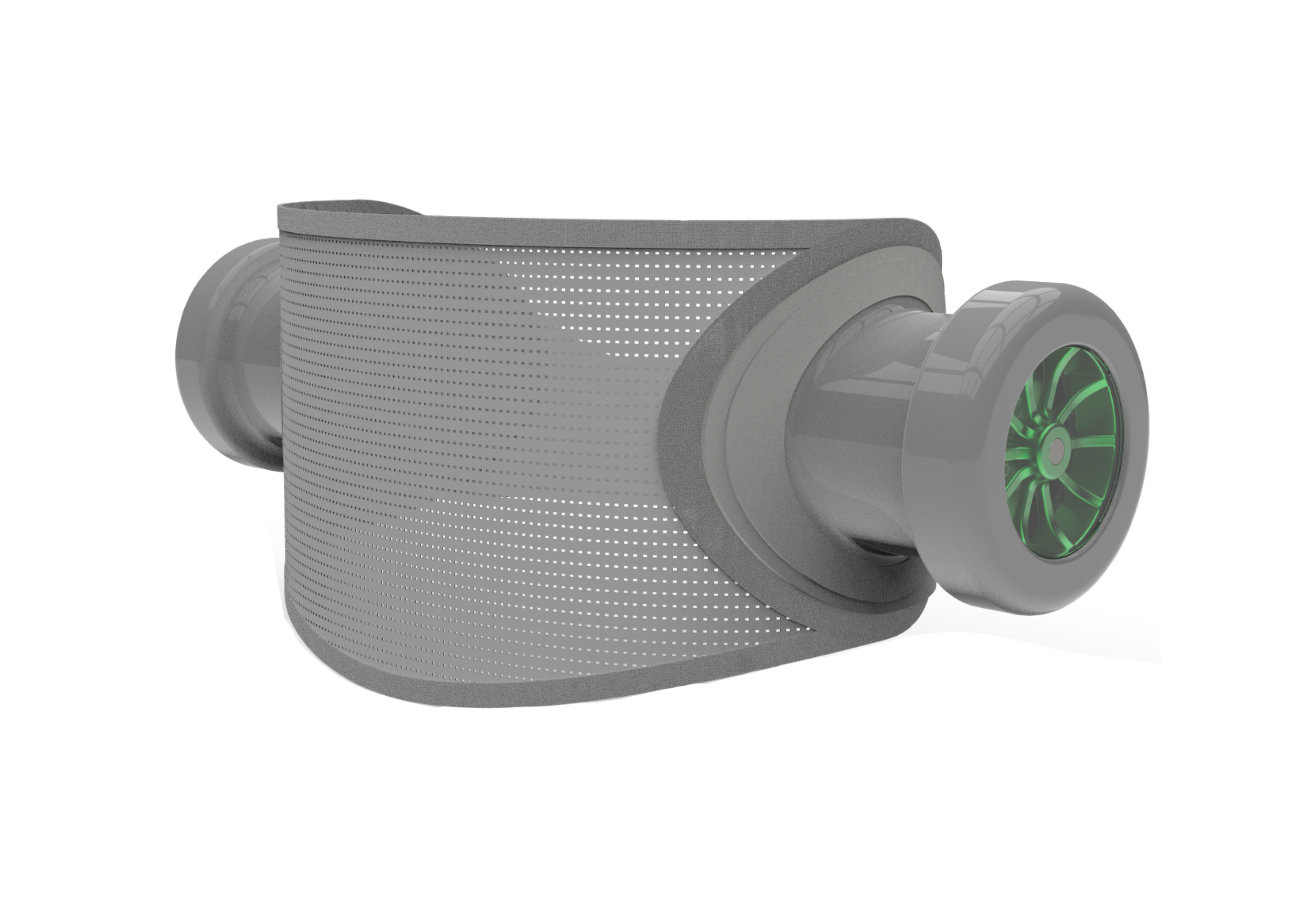

The Automatic Balancing Device (patent pending) solves the issue of falling entirely by preventing falls. When the user becomes imbalanced, gyroscopic sensors in the device detect the angle of the user's fall and how quickly they are falling. Motors then rotate flywheels in the direction opposite the fall (ex: spinning backwards for a forwards fall) to create a strong torque that counters the momentum of the fall. This torque is strong enough to return the average user completely to their feet from falling as far as 30 degrees forwards or backwards.

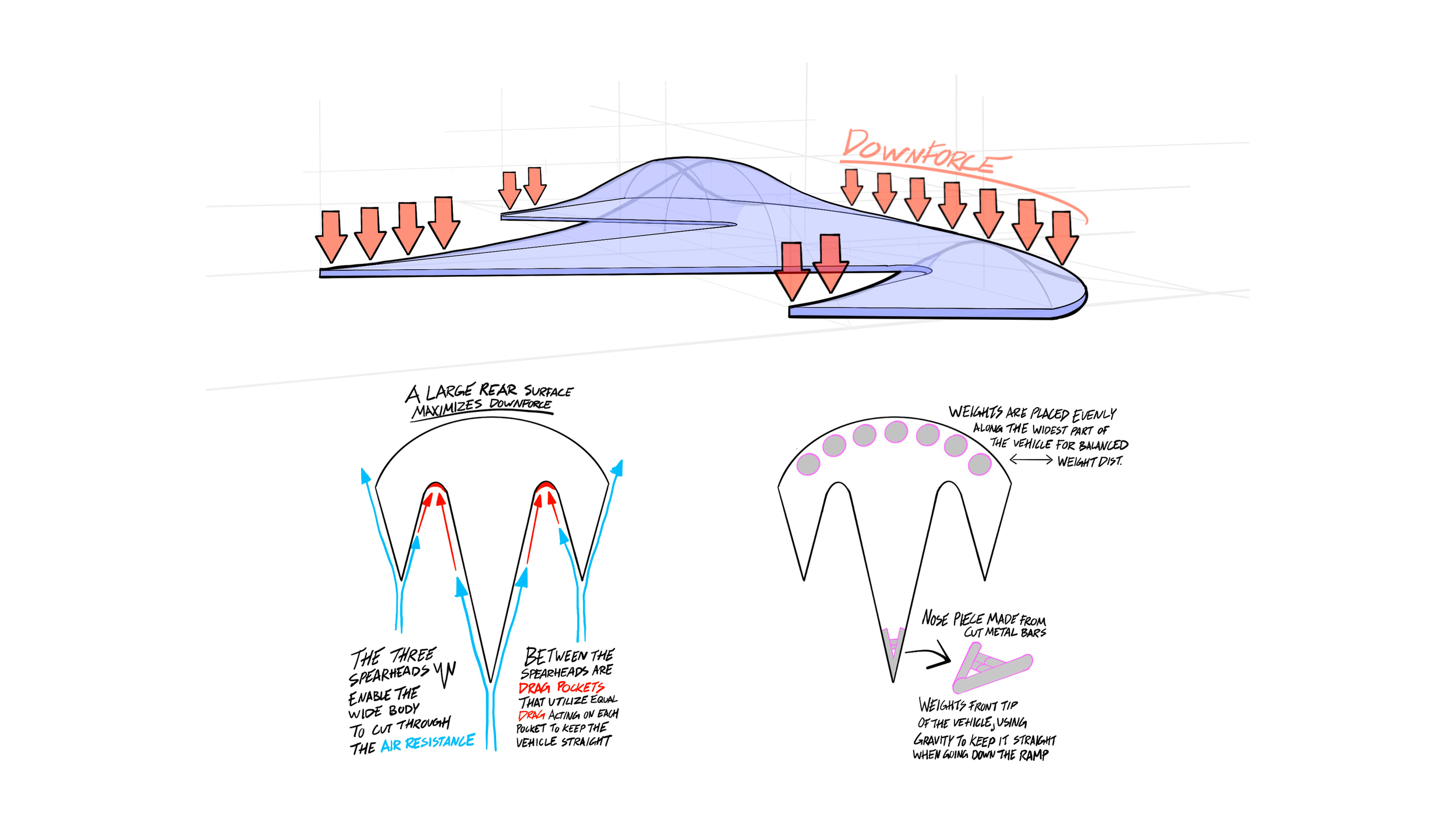

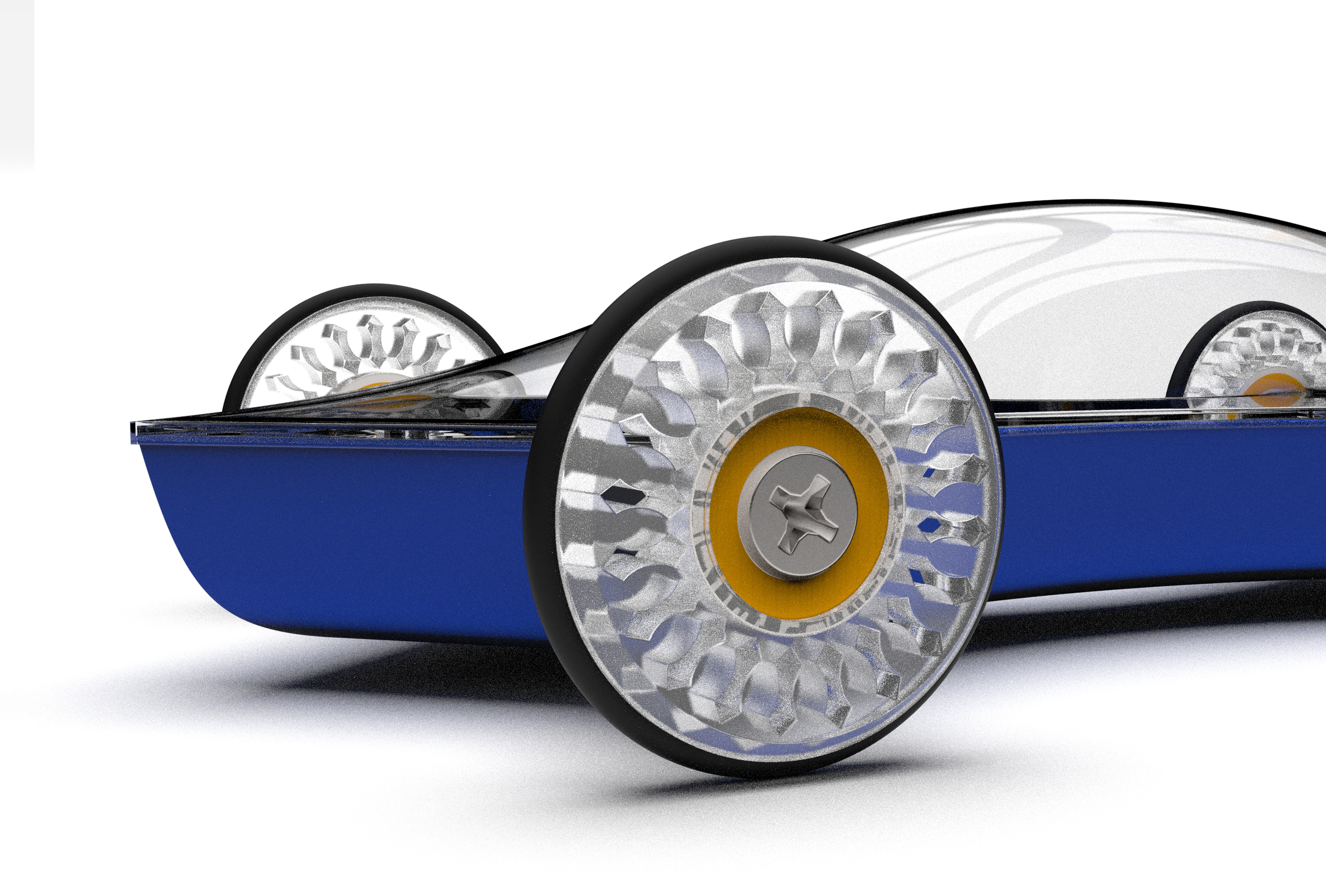

Ramp Race Car

The yearly SUIID Ramp Race asks juniors to use CAD modeling and fabrication skills to produce a race car that will compete in several events. Having awaited the Ramp Race for years at SU, I had strong ideas of what I wanted my car design to accomplish

Visually interesting - deviating in form from the templates/example materials

Tuned for performance - aerodynamic, form following function

Intentional/Thoughtful Design - every part added onto the car is thoughtfully implemented and not tacked

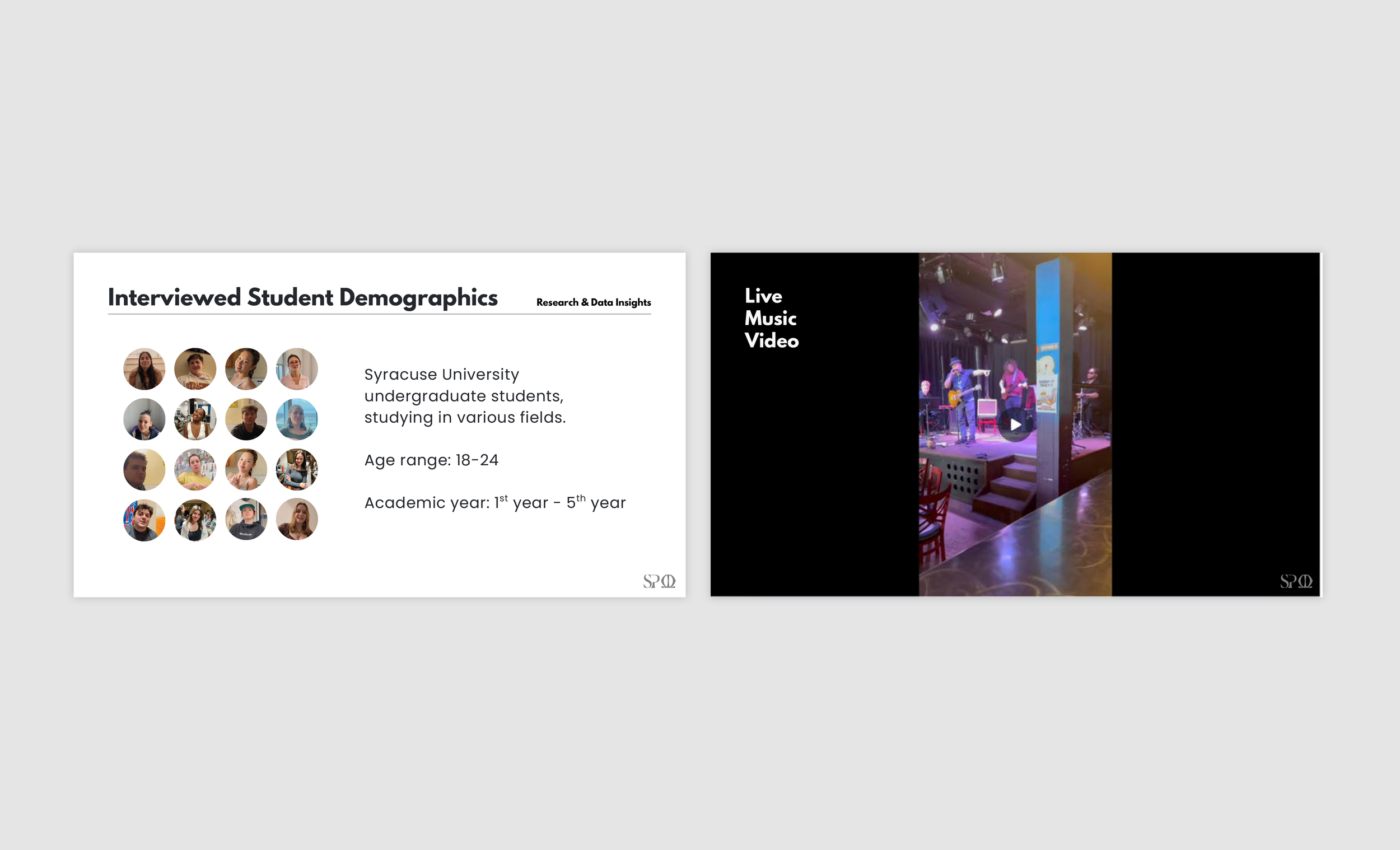

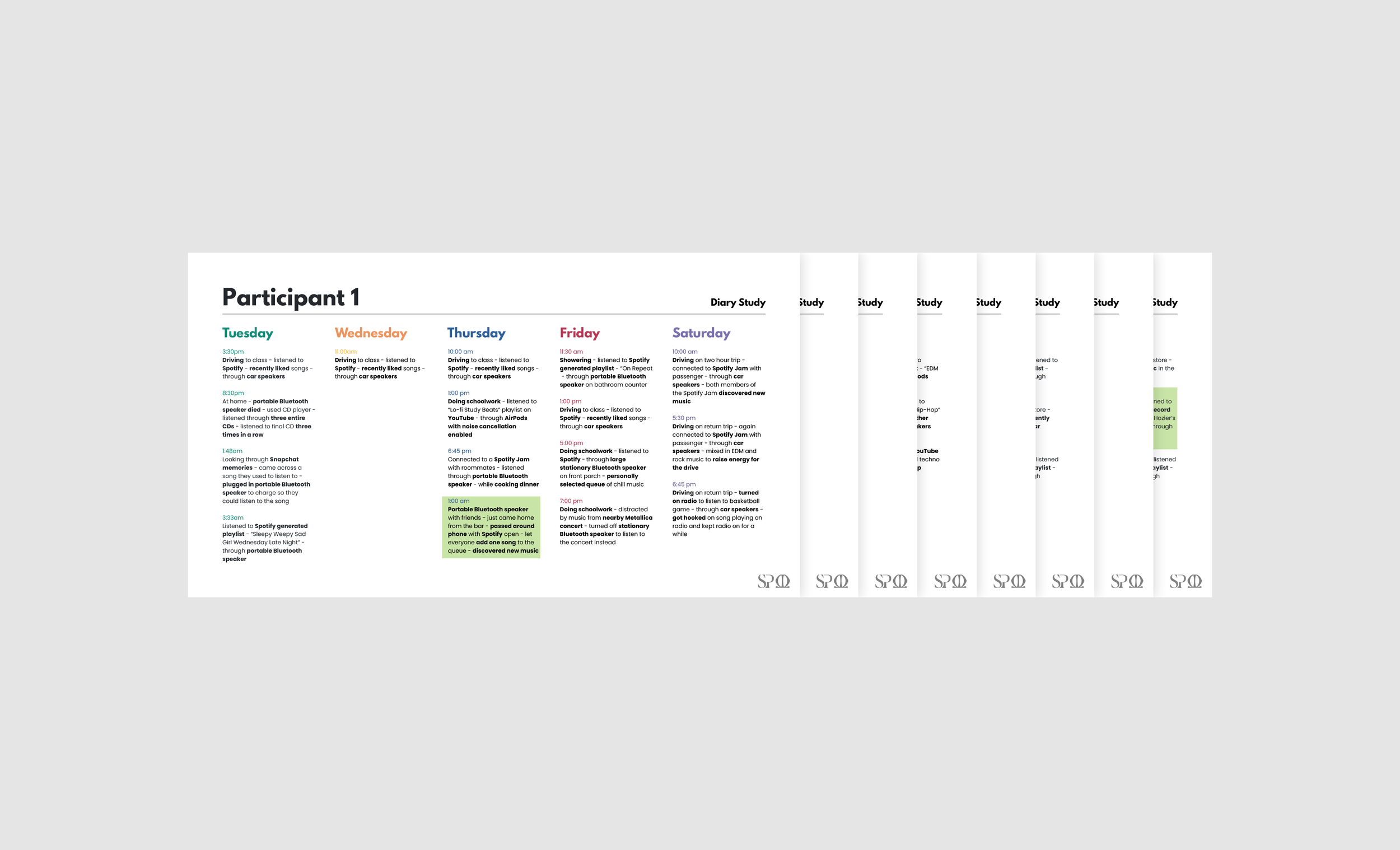

The future Of Music @ BOSE

What began as a school project about Gen-Z’s music listening habits evolved into a multi-part presentation that we tailored for, and presented to, the design teams at Bose Corporation headquarters.

My classmate Sophie Pirondini and I utilized extensive primary and secondary research to dive into the attitudes, trends, and interests of Gen-Z pertaining to music consumption, experiences, and products. We then identified areas of opportunity in the audio market using this research and provided Bose with several product concepts to capitalize on these areas.

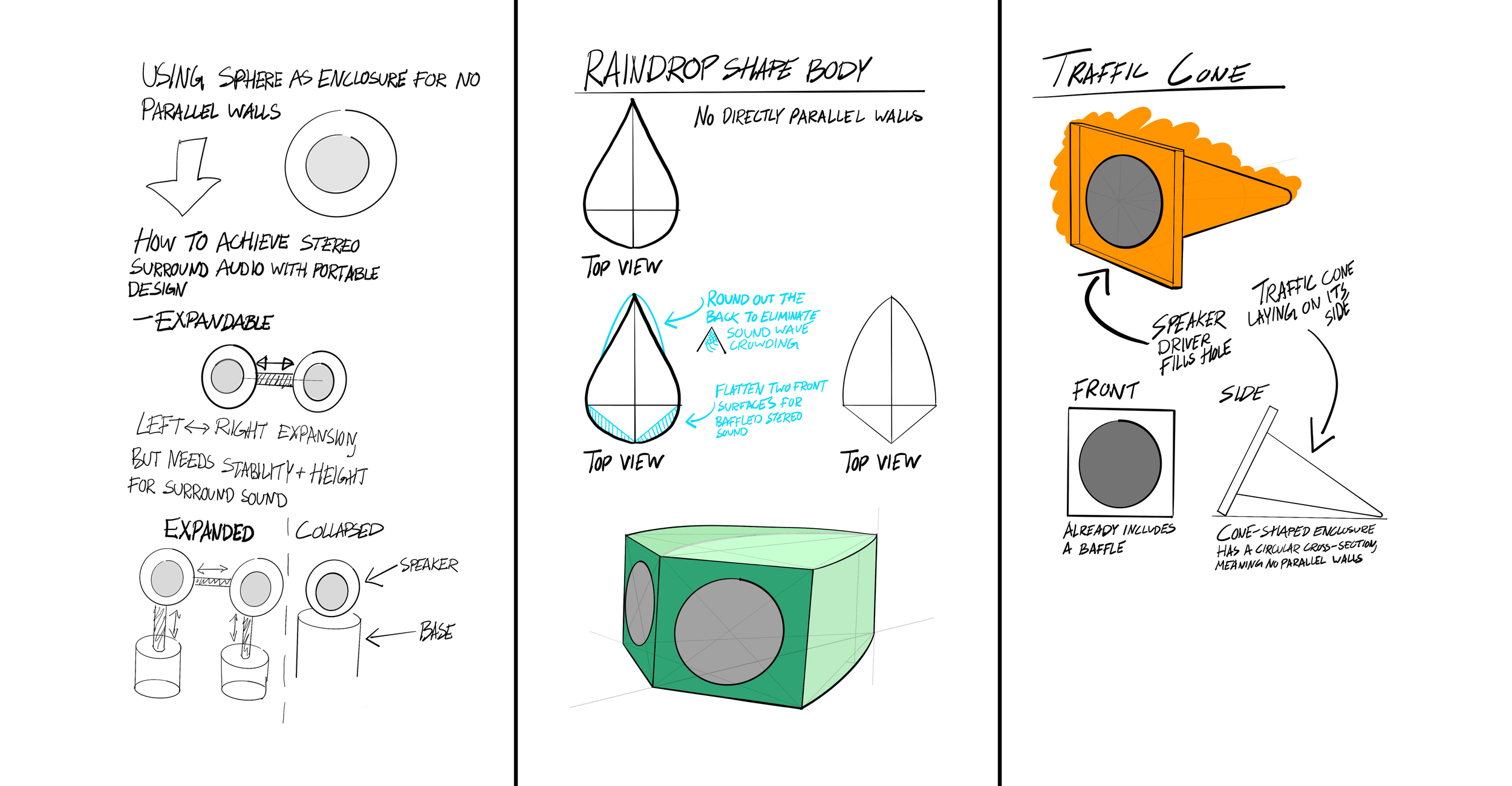

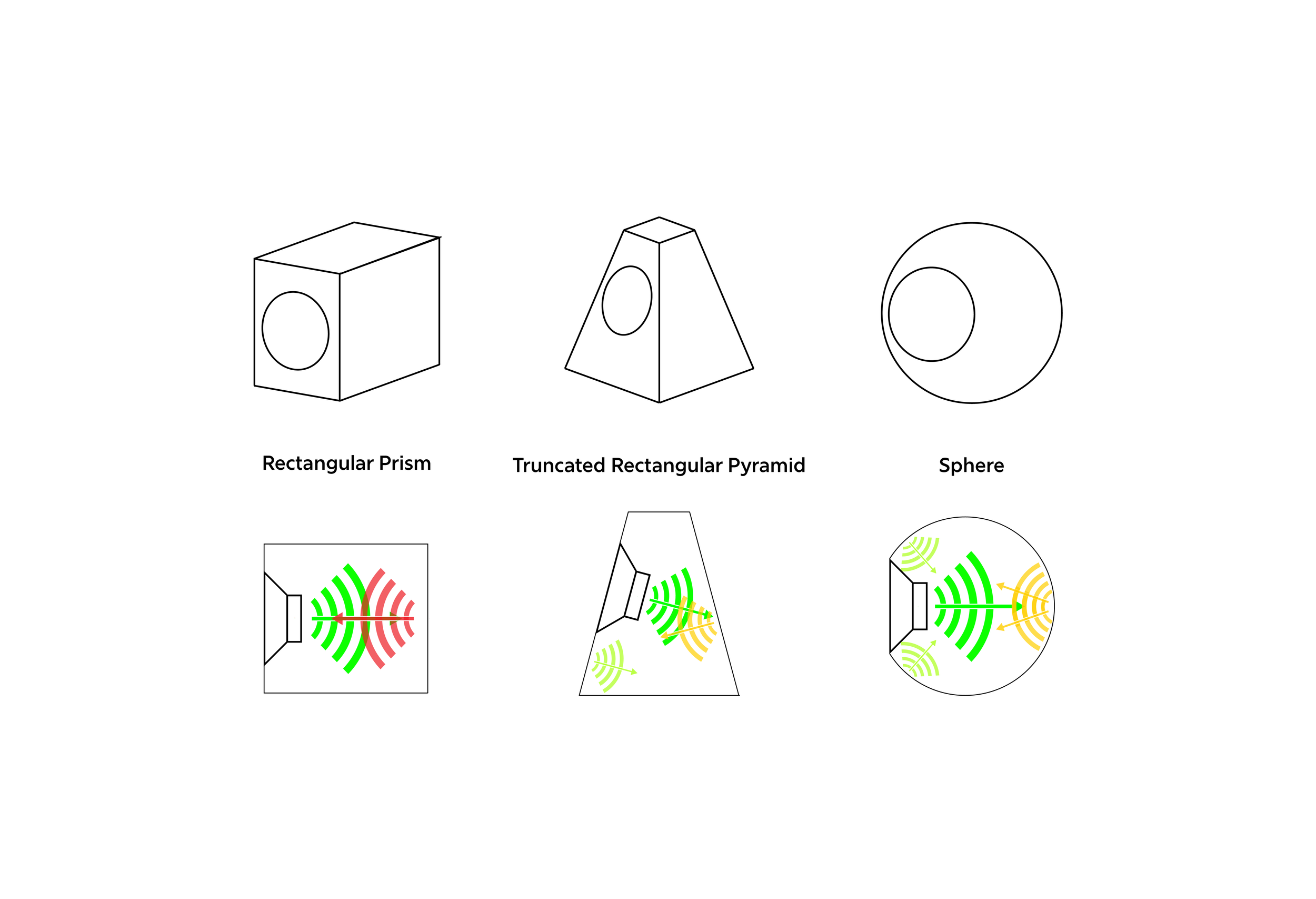

Traffic Cone Speaker

Assigned to design and construct a fully-functional Bluetooth speaker, I wanted to provide strong sound quality while deviating from the geometrically simple and aesthetically dull speakers currently populating the market. I saw an opportunity with the traffic cone, which has a form that lends itself to quality acoustics while still being fun and visually interesting.